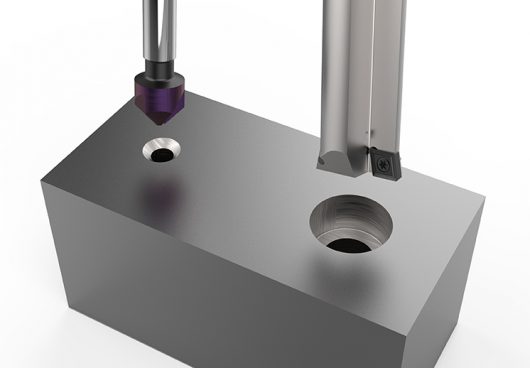

During a machining process, countersinking and counterboring are mechanically similar operations but with very different purposes.

What are the differences ?

Countersinking is a mechanical process that consists in the removal of burrs and the creation of slots for countersunk head screws so that they do not protrude from the surfaces of the machined pieces, once inserted. The countersinking can have variable angles of entry (mainly from 60 º to 90 º) to accommodate just the flat heads of different types. Specifically, the sizes of the three-flutes countersinks (DIN 335) are the most widely used and suitable for the installation of screws.

Counterboring is an operation that allows to realize a cylindrical hole with the flat bottom that widens another coaxial hole. This mechanical machining is carried out with appropriate counterbores, when the head of a fastener must not protrude from the surface of the workpiece.

Our solutions

As for the mechanical operations mentioned above, the solutions proposed by Angelo Ghezzi & C. Spa, in the ILIX range, include three-flutes countersinks, cylindrical or taper shank, in HSS-Co or in solid carbide, uncoated or coated, with execution 90 or 60 degrees.

For more demanding operations, always within the ILIX range, unequal-pitch countersinks have been introduced to limit or eliminate the natural vibrations generated during processing.

In the case of massive productions you can count on tools with indexable inserts, introduced in the Talicarb program, suitable for the execution of screw seats and various flares of the holes.