In many companies, used tools are sent for scrapping as soon as they are worn or damaged. Sometimes this is a useless and expensive waste, because some tools can return to full operation with a regeneration process that brings them back to their initial conditions, allowing the customer to achieve the maximum benefit from his initial investment. The good result of a reconditioned tool is guaranteed by several processing steps: initial inspection of the damage, reconditioning process, complete restoring of the original geometries.

In many companies, used tools are sent for scrapping as soon as they are worn or damaged. Sometimes this is a useless and expensive waste, because some tools can return to full operation with a regeneration process that brings them back to their initial conditions, allowing the customer to achieve the maximum benefit from his initial investment. The good result of a reconditioned tool is guaranteed by several processing steps: initial inspection of the damage, reconditioning process, complete restoring of the original geometries.

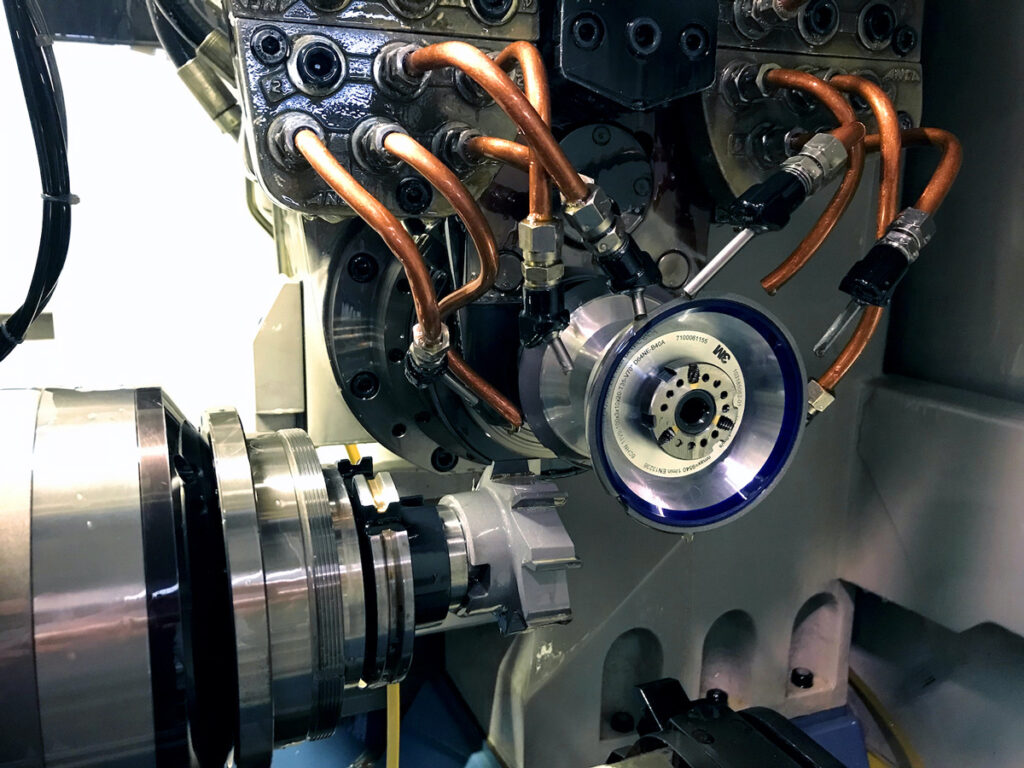

The specific regrinding operation is also part of the tool reconditioning. It is a production process carried out with the use of abrasive systems or discs for the restoring of worn cutting tools.

The tools in question can be put back into operation by regrinding, returning the cutting edges of the tool back to the correct cutting geometry.

Through this operation it is possible to recondition the surface quality of the cutting edge, improving not only the cutting quality of the tool, but also its tool life and consequently its profitability.

Obviously not all tools can be regrinded and this possibility will essentially depend on their condition.

Our proposal

The Angelo Ghezzi & C Spa company is able to regenerate a damaged tool.

In our production units, thanks to years of experience with the best of recent technologies, we are able to give the reconditioned tool an application performance equal to its original state.

We specifically deal with both tools with indexable inserts and solid carbide tools.

Regarding tools with indexable inserts, the reconditioning operations may mainly concern the restoring of the insert’s seats.

Concerning solid carbide tools we can guarantee a regrinding service and possible coating for drills, endmills and indexable inserts (for the latter the service is reserved only to the ILIX-AG Drill series).

The regrinding service offered by our company respected all the same parameters of the manufacturing process.

We can therefore guarantee the use of specifically selected wheels, a confirmed and guaranteed CNC programming to replicate the original tool geometries and the same machines used exclusively for regrinding in order to guarantee a high level of precision.

When required, after grinding, the coating is carried out again together with a new surface treatment.

At the end of the process, thanks to quality control, our user will have the guarantee that the quality and performance of the tools regrinded by Angelo Ghezzi & C. Spa will be identical to that of a new tool.